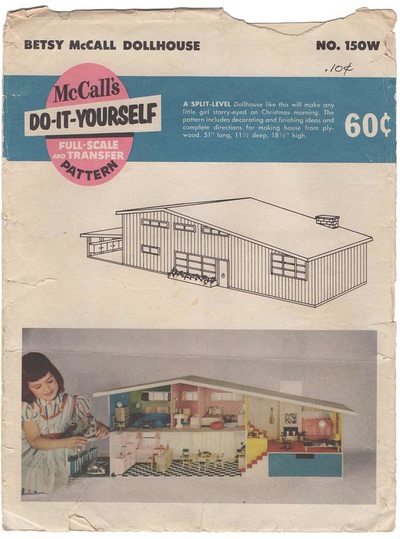

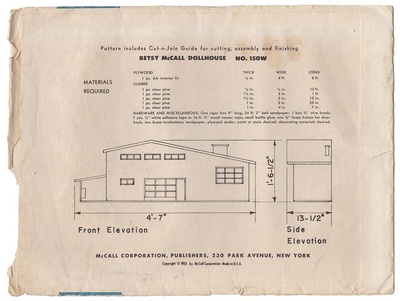

This page records my thoughts as I created this model. I started thinking about this project in November 2014 when Rick Beyer and Elaine Doran approached me and asked if I was interested in creating a model for an exhibit to be staged by the Lexington Historical Society in May of 2015. They asked me based on my prior efforts in creating paper models of historic houses in Lexington. But, they wanted the model to be much larger than I had ever done in paper, and I decided to somehow use foamcore so that the sides would be stiffer.

The exhibit got postponed until June (good thing). Here are some milestones:

- November 15, 2014: Took my first photographs of the house. I went back several additional times.

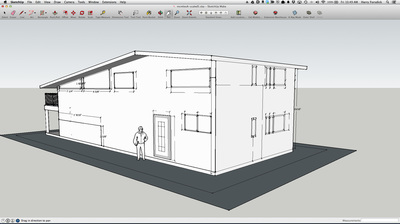

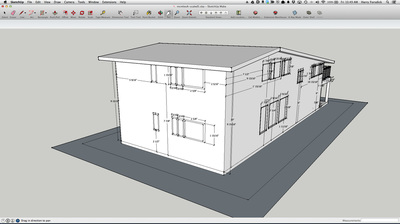

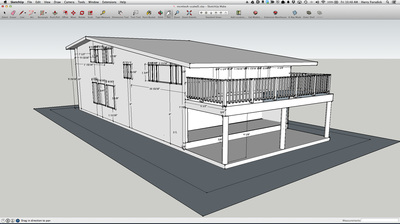

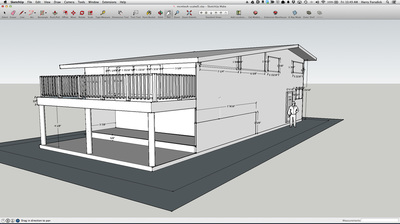

- December 28: Made my first Sketchup model of the house

- January 15, 2015: Left Lexington for the South for an 8 week vacation

- March 15: Returned from vacation.

- April 6: Started making Sketchup model changes again.

- Too many points to list ...

- June 12: Made last design changes.

- Frantic, all consuming, activity to finish the model: this is one of the few times I've actually "finished" a model...

- June 17: Delivered model to Lexington Depot with just a few touchups to complete.

- June 19: Exhibition opens.

What follows are notes of my thoughts and changes in plans as I worked on this model. Lot's of things changed as I went through the process of exploration, design, experimentation (anybody need a lot of unneeded coffee stirrers?), iteration, test builds, and finally building the actual model.

I have learned a lot, which for me is the reward of doing this.

In all of the photo galleries below, move your pointer over a thumbnail to see a caption, click on the thumbnail to see a larger size of the picture.

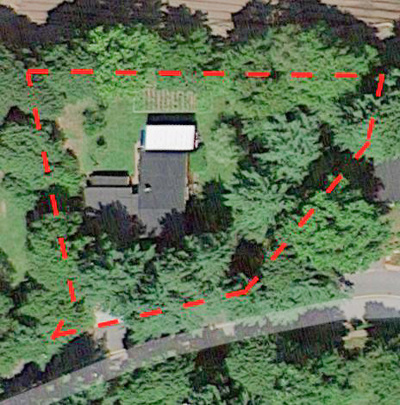

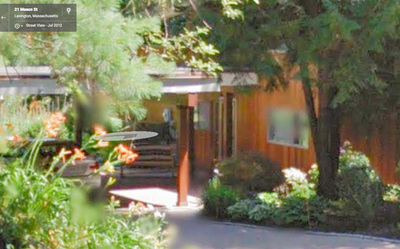

Photographs of the house as it exists in 2015 after several alterations.

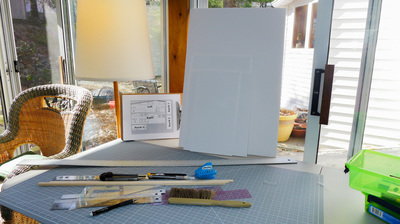

Model with color finishing, and additional back deck, carport and storage shed.

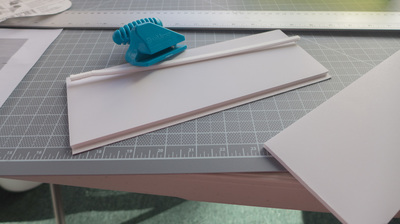

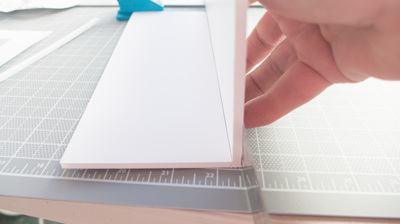

Plain white surfaced model

Building the model

First Assembly of Foamcore

Similar Models

Siding

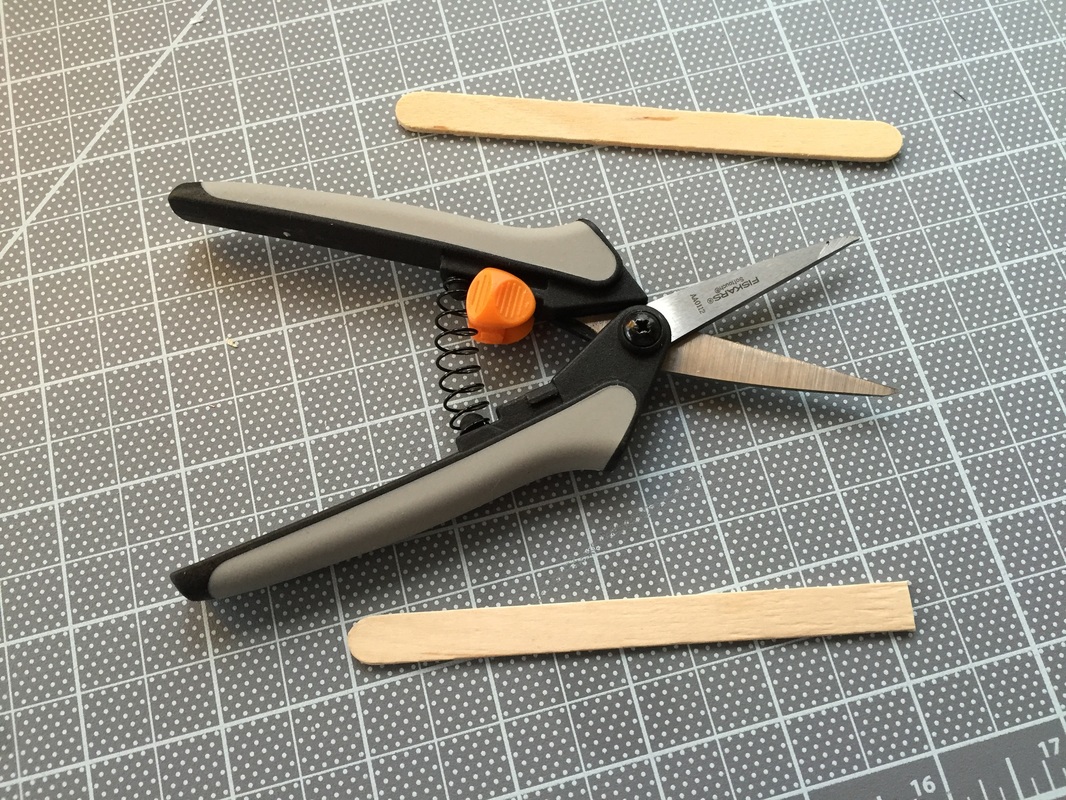

- utility knife (too hard and after fatigue, dangerous),

- paper cutter (wood too hard),

- going to a woodworking store (no solution, but recommendation that I go to an auto body shop to see if they would use their hydraulic metal shear to cut off a long row of the ends),

- talking to the auto body guy who said such a metal shear was actually not very sharp, but that he thought an electric drill with a grinding sanding surface followed by smaller sandpaper would do the tick

and finally,

- coming home, ready to get out my electric drill when I notice a small, but very sturdy Frisker's AA0112 shear sitting in my box of craft tools. I try it out on the end of one stick and with a moderate amount of pressure it cuts the rounded end off leaving a little bit of compression on the stick end, but perfectly reasonable.

So, it just goes to show that it takes a couple of tries before you get the right solution.

Siding Color

Cutting holes for doors and windows

Back Porch: The Platform

The Roof and Cross Beams

Siding, Windows and Doors

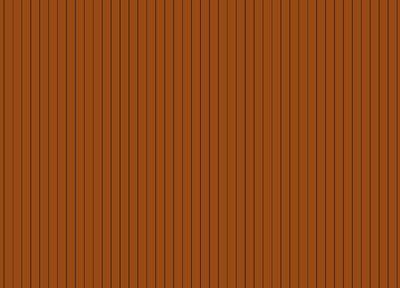

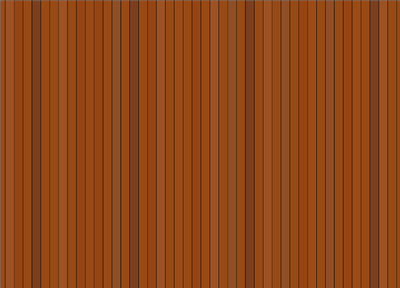

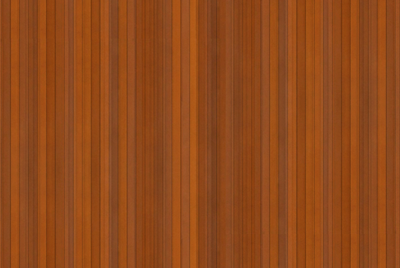

One of the major attractions of this house was the natural stained wooden siding which had weathered naturally over many years. The problem when modeling this is to create the variabality in color, texture and the sense of it being vertical boards. I first worked on the color, consulting the Minwax color charts for wood stains (see above). I eventually settled on some combination of cherry and pecan which adds a little yellow to the red-brown of cherry. So, here is the progression of how I arrived at the final technique for doing the siding.

Progress as of April 24, 2015

May 2: End of Experimentation and Design

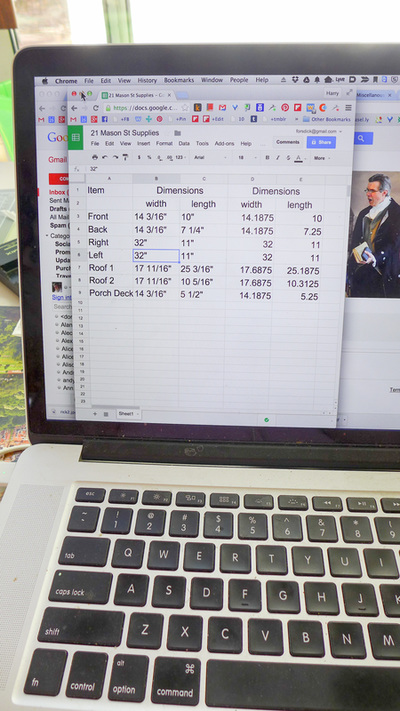

- In a model this big, accurate measurements make a big difference in parts fitting together.

- Seeing the actual size of a model helps you understand the issues you face and techniques you can use.

- Masking tape is a great tool to attach things in "draft" form. Get some wide (1 1/2") masking tape and use your sharp knives and metal rulers to cut into many smaller strips that can hold parts together.

- Freehand line drawing or cuts even guided with a straight edge over long distances are difficult to get correct and aligned. In particular for cutting where significant pressure is needed. It is better to step up a bit and spend more money on tools that are meant for this task (like the series of FoamWerks foamboard cutters.

- Elaine Doran gave me some very good advice: settle on one type of decoration and use it throughout. At one point, I was considering creating siding out of various types of thin wooden strips stained to the color of the siding on the house. Then I started exploring the windows and doors using photographs pasted to a stiff thin board, with a layer of thin plexiglass and a wooden frame to be applied on top of the wooden siding. After several attempts at creating these model windows, on a lark, I tried to see what I could create entirely in a photo editor printed on paper and affixed to the side of the foam core. The results from my consumer grade ink-jet printer were very promising, especially after I experimented adding strong shadows derived from trompe l'oeil artistic techniques. When printed by a local printer on semi-gloss paper, this form of modeling the details of windows and doors is very realistic. These experiments lead to the following summary observationL

- High resolution photography combined with high resolution printing on heavy semi-gloss paper is an effective technique to cover surfaced in models. When combined with trompe l'oeil artistic techniques, very nice models can be created with very effective use of time. These models do not have the same "miniature" characteristics of models built with discrete parts, but they have a unique realism.

So, now I have taken apart all of the tests and experiments and am about to measure and cut the entire model again, this time armed with the things I learned since the middle of April.

May 3, 2015: Parts of the model beyond the house

In any case, in addition to the house, there are several other features I would like to include in this model. Again, taking the advice of Elaine Doran, I am not going to mix modeling techniques and so with few exceptions I am sticking with foamcore 2D representations of most of the extra features. Here are some of the extra features that I am thinking about:

- Foundation level shrubbery

- Trees of various heights and types

- Period automobiles for the driveway

- Period dressed people representing the occupants of the house

- Earth berms that were created on the left and street sides of the house and carport

May 22, 2015: It's Been Awhile

- Retaking photos of the house, making sure I have good photos of each of the features of the house, including the carport and shed, the windows and doors, ground covers (driveway, front door patio), terrain, and anything that didn't correctly register with me on my first photo tour (in particular, the details of the rear entrance at the back of the house).

- Lessons Learned: It takes several passes of looking at an existing structure to see all of the features. Photographs are a good, but not a perfect way of helping in this area because photos are static and don't anticipate looking at things that require detailed exploration. I've learned this the hard way by incorrectly modeling the back of the house, as well as the carport. The back of the house was just complex, messy and an add-on. With the carport, I just assumed that the roofline would mimic the roofline of the house. I was wrong: it is a flat roof which is at the same level as the breeze way and of the same design.

- Making updates to the SketchUp model. Although it turns out that the actual SketchUp model isn't actually needed for the final construction, it has been extremely for the scale model dimension measurements. It is the first place I go when making any changes to the model.

- Creating 'sides" of the model in my image editor (PaintShop Pro, similar to PhotoShop). I created all of these images at 600 dpi -- probably overkill, but at least I have the necessary resolution to do anything I need to do with them.

- After consulting with Lexington Graphics, I have settled on printing on 12" x 18" sheets of 100 lb cover stock on their Xerox Color 700 Digital Press.

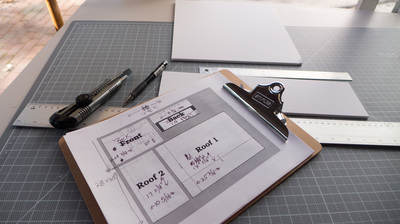

- I will use some of the printed images as construction material that is cut in sheets of various lengths and widths as I build up the model from foam core. So, for example, I will print 6 sheets of roofing and then cut it to fit the various roof surfaces. Other printed images (the sides of the house and the inside of the shed are images built up out of siding image overlaid with various windows, and concrete surfaces and well as the shadows such windows and doors would cast. Then this side is cut to shape and applied to foamcore.

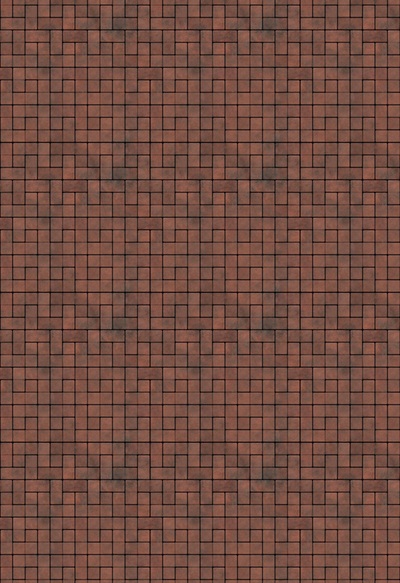

For example, here are samples of the siding, roofing, driveway and mulch materials:

The other types of printed images are the four sides of the house. Here is one side which is 32" wide and must be printed on 2 12"x18" sheets. I am worried about how to make the join in the middle without seeing a seam. The roofs are similar surfaces that will need to be formed out of multiple 12"x18" sheets .

- Paste the four surface sides of the house to foamcore board in their original untrimmed 12"x18" dimensions (the long sides are printed on 2 12"x18" sheets and thus must be carefully seamed together).

- Paste the surfaces of the roofs to foamcore board cut larger than dimensions of the 5 roof segments (2 for main house, 2 for carport, 1 for breezway. Again I will have to piece together multiple 12"x18" roof surfaces.

- In general, if I had to do this again, I would have printed the larger pieces on one continuous sheet of paper which LexGraphics can do.

- Paste the upper surface of the porch deck to a piece of foamcore cut larger than the dimensions of the deck. Paste unprinted white 100 lb cover stock to foamcore cut larger than the combined dimensions of the other 5 surfaces of the deck platform. These 5 surfaces can be cut so that a single cut produces the edges of two pieces.

- The roofs all need to be made from multiple thicknesses of foam core (or built as a rectangular box) with the roofing material pieced together on the top and plain white paper applied to the edges. The bottom of the main roof and the shed roof can be white also. The bottom of the carport and breezeway roofs is the same as the house siding.

- The beams on the house and carport roofs and and support posts on the porch, breezeway and carport will be made out of multiple layers of foamcore glued together and then covered with house siding material. Some posts may have a band with a shadow around the foot of the post.

May 31 The railing for the deck

Prior to cutting and assembling, I colored the wood with a Copic Sketch E09 (Burnt Sienna). marker. I just discovered these amazing pens are refillable with Copic alcohol+pigment in over 350 colors. They are perfect for staining wood parts to a model, as well as touching up cut edges in paper that show the white color of the paper. Unfortunately, I discovered that Copic EO9 Burnt Sienna color is not correct -- it comes out with too much red. Instead I will have to order online (because the Dick Blick store near Fenway Park carries a lot, but not all of the colors in the Copic line of markers). As it turns out, to get the color of the model, I probably should use two colors, but I'm not sure I want to do that. In any case, something lighter and with more brown is probably the right color.

So, it looks like I will be building a second railing to get it right. I'll see how it looks on the current deck, and decide later whether or not to rebuild and recolor a new railing.

June 3, 2015: Final Design

June 4, 2015: She Likes It!

In any case, I first showed Elaine the SketchUp model to give her a preview before we went into the dining room where I had put together the pieces for the first time. Since I put things together with masking tape so that I could preserve my flexibility until the last moment, I wanted her to see the intended look.

It is impressive when you see it all assembled, with masking tape or not. Elaine liked it, and as I suspected needed to see the actual model to appreciate how good it can look. Here are some pictures I took yesterday.

RSS Feed

RSS Feed